Replacement Friction Pad Kit for Reese Steadi-Flex Weight Distribution Systems

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.

- All Info

- Reviews (17)

- Q & A (0)

- Videos (1)

- Photos

Reese Accessories and Parts - RP58527

- Weight Distribution Hitch

- Sway Control Parts

- Friction Pad

- Reese

Replaces a friction pad kit for your Reese Steadi-Flex weight distribution system (RP66559, RP66560, or RP66561).

Features:

- Replaces a friction pad kit for your Reese Steadi-Flex weight distribution system (RP66559, RP66560, or RP66561)

- Automotive-grade friction material coated steel construction

- Quantity: 1 friction pad kit

58527 Replacement Friction Pad Kit for Steadi Flex Weight Distribution Systems

California residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Video Transcript for Reese Weight Distribution RP58527 Review

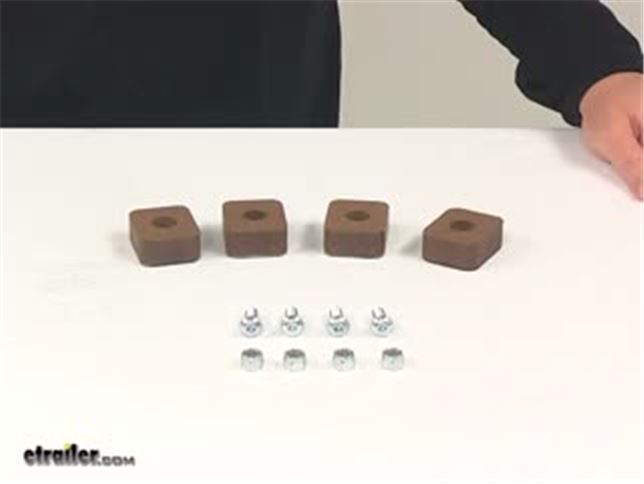

Today, we're going to be taking a look at the replacement friction pad kit for Reese Steady-Flex weight distribution systems. This kit's going to replace the friction pads on your Reese Steady-Flex weight distribution system. Part numbers RP 66559, 66560 and 66561. These are made from a durable steel construction. They're going to feature the nice automotive grade friction material. These pads line the brackets to help correct any sway that may occur due to winds, curvy roads, or sudden maneuvers.

It's going to come with one kit. Each kit is going to come with four pads. That's two per bracket. It's going to come with the necessary installation hardware. That's going to do it for today's look at the replacement friction pad kit for the Reese Steady-Flex weight distribution systems.

Customer Satisfaction Score:

95% were satisfied with this product

5% of customers were not satisfied

- Wrong item was ordered

Customer Reviews

Replacement Friction Pad Kit for Reese Steadi-Flex Weight Distribution Systems - RP58527

Average Customer Rating: 4.6 out of 5 stars (17 Customer Reviews)

Replaces a friction pad kit for your Reese Steadi-Flex weight distribution system (RP66559, RP66560, or RP66561).Deducted 1 star for no installation instructions. Note this is a medium difficulty job only due to the de-installation of old pads - the abraded brake pad material filled in the screw hole and packed in tight under temperature (friction caused by the WD bars) forming a solid brake pad. You will need a 3/16 hex socket, ratchet, 12" extension (length dependent on your trailer setup), cold chisel, hammer, small flat bladed screwdriver and angle grinder (if unlucky).

The first pad I tried digging the hole out with a screwdriver and pick. Even after cleaning out the hex head and around the head very well I still stripped the hex head (the male hex bit spun inside the female bolt head). Apparently some of the residual pad material had "glued" the bolt head down and I couldn't dig it all out. Next I used a cold chisel and a hammer, hitting the pad between the friction pad material and metal backing plate to pop the pad off. Success! The head was now exposed and I used an angle grinder to grind the head off and drove the remaining bolt out with a hammer & drift.

Now for the other side front pad. Here is what I did and it was easier. First separate / pop the pad off the backing plate with a cold chisel & hammer like the first pad. Now you have full access to the bolt head and can thoroughly remove all residual pad material from on/in/around bolt head with a small flat bladed screwdriver and pick. Clean the female hex recess of the bolt head extremely well. Helpful hint: Next assemble the 3/16" hex socket and extension but don't attach it to socket wrench yet. Put this into the bolt head and hit the end of the extension with a hammer. This will drive the hex bit into the bolt head, even if there is residual pad material still in the hole, giving it better bite. Attach socket wrench to extension, keep your weight on ratchet driving the hex bit into the bolt head and now try to loosen the bolt. It should break free. If not and the bolt head strips out cut the @%^ bolt head off with the angle grinder lol. YMMV

Side note: the dealer apparently skipped step 31 in the installation instructions so just my front pads wore down. This has been corrected.

Quick, prompt professional service. Thank you,

I just received these and have not yet used them. They do appear to match original hence the five stars. These were back ordered but etrailer did a good job of keeping me informed of delivery. I have been happy with the performance of the Reese Stedi-flex system for one and a half seasons of light use. I am disappointed that 2 of the pads separated from the metal backing even though the pads were still in good shape. Had I considered the high price of replacement pads I would have considered a different system.

David

8/17/2022

I was able to glue the original pads in place with gorilla glue and have kept the replacement kit as a backup. The system has worked well.

My first trip after replacing the pads, one of them crumbled on the ends. I rotated the pad around to get what I could out of it. They seem to be wearing a little quicker than the original pads. Otherwise they’re doing the job.

Steven L.

6/16/2023

OK! One pad partial crumbled on the first use, otherwise they’re holding up.

While it was disappointing to have the friction pad on my fairly new Reese Stedi-Flex WDH break off as I removed the system etrailer did an excellent job of reviewing the problem, speaking with the manufacturer, and overnighting the parts to me for the repair. For anyone with this system I recommend carrying a good quality 3/16 hex socket in your took kit. The factory install on the bolt would not give using a cheap allen wrench. With a good hex socket the parts are simple to replace. Thank you Emily for excellent service.

Bruce D.

7/30/2018

The Reese WD Hitch performed well half way into a long trip. After about 3,000 miles one of the ablative pads broke off and it took several hours of trying to call Reese to figure out a solution. Finally etrailer stepped in to solve this by sending me the replacement parts. I still am getting uneven wear on the pads but no adjustment seems to remedy that. If I were starting over I would buy a hitch system with a different system for sway control. The installation of the sway control brackets resulted in an uneven fit on the trailer A frame. The bottom bolt had to be ed into a hole about an inch below the trailer frame and when tightened to specifications it bowed out somewhat resulting in uneven force against the A frame. I reported this to Reese and got no reply. If you have any suggestions I would appreciate it. We are about to take some more trips so it will be interesting to see how the system performs.

Right parts, delivered on time. Thanks Kimberly for the help!

GD Imagine 2970RL (8,995# GVWR) w/ Ford F250: I swapped out my Fastway Equalizer e2 for this hitch, not because I didn't like the e2, but the dealer undersized the hitch (10K w/1K tongue weight rating), and it didn't offer the tongue weight rating I needed. With modest cargo and a full fresh water tank, I was closer to a 1200# tongue weight, which is right at 12%-13% of the total trailer weight, and really ideal for WD/sway control towing. I've towed about 500 miles so far on this hitch, and it does what it's intended to do. If any sway is introduced by a passing truck or whatever, this hitch knocks it right out quickly, and it is very minimal to begin with. I will say there was a bit of a 'wear in' period the first 50-75 miles. The reason for that is the WD bars come painted at the point where the bar meets the friction pad (Fastway left this part bare metal), and the paint makes the bars slick, which does not help with sway initially. However, once the paint wears off and you have metal-to-friction-pad contact (like the breaks on your car), it works perfectly. Reese should consider not painting this part like Fastway; I mean you wouldn't paint the break rotors on your car for that reason. Step #31 is also very important. Your clamping bar mount will not sit perpendicular to your frame if you've done this correctly. The bottom will be kicked forward toward the tow vehicle slightly. It look's a little weird to us OCD types, but it's critical to make sure the WD bars sit flush on both friction pads equally. The only reason I'm taking a star off is the friction pads are a wearable item, and $100 for a set of four, that's an additional ongoing expense that other typical WD hitches do not require. Additionally, I'm not a big fan of the spring bar cover design and the tiny little cotter pin that holds it closed. Everything else seems super industrial strength, then there's this teeny tiny little hole and cotter pin (that I might lose) holding the cover shut, and your WD bars in place. Reese could have done a better job on the design there IMHO. Otherwise, it's a great hitch and is working fantastic on my set up.

The pads on my Reese Steadi-Flex hitch take a beating due to the high tongue weight (1200 lbs) of my trailer. One of the original pads disappeared after only 4 trips but the replacement pad is holding up well along with the other three originals after 13 trips.

The delivery of the product was very fast, and was glad that they had them in stock nobody else had them.

Thanks so much !

The brake pads came as requested and were easy to replace. Though they seem to be a quality product they are expensive for what you get. Not e-Trailer's fault.

Even though the order was backed ordered you constantly kept me updated as to target ship dates.

Got the ordered on time and it was exactly what I ordered. Thanks

See what our Experts say about this Reese Accessories and Parts

- Replacement Friction Pads for the Reese Stedi-Flex Weight Distribution SystemThe Reese Steadi-Flex Weight Distribution System w/ Sway Control - Trunnion - 10K GTW, 1K TW # RP66559 utilizes friction pads that will eventually wear down as you stated. It will take a long time for these pads to require replacing, but the Replacement Friction Pad Kit for Reese Steadi-Flex Weight Distribution Systems # RP58527 are available and easy to replace with a simple screw and nut.

view full answer... - Troubleshooting Uneven Wear on Friction Pads for Reese Steadi-Flex Weight Distribution SystemThe pads on the Reese Steadi-Flex # RP66560 systems are designed to wear down over time which is why the Replacement Friction Pad Kit # RP58527 exists, however you should be experiencing fairly even wear so if just one end is wearing down then some adjustments need to be made. If you check out step 31 in the linked instructions (see attached photo) it calls for adjusting the friction pads so that they settle flat against the spring bars. If you haven't been doing that when hitching up...

view full answer... - Can Arms of the Reese Steadi-Flex be Installed by HandI spoke with my contact at Reese and he said that depending on how much the trailer weighs you may or may not be able to lift the arms of the Reese Steadi-Flex # RP66560 without the tool. Even if you were able to lift the arm in place by hand this isn't advisable because you could potentially injure your hand doing so. I'm not sure what you mean by "reasonably high" but the instructions recommend raising your tow vehicle/trailer up about 4" with your trailer jack. If that puts you close...

view full answer... - Should Tongue Weight be Measured When Choosing Weight DistributionI definitely recommend finding your trailer's tongue weight when choosing a weight distribution system. You need to have the trailer loaded like it will be when you're towing it, and you also need to add in any weight you put behind the rear axle of the tow vehicle because this counts as tongue weight when it comes to weight distribution. You want a weight distribution system that has a tongue weight range that covers the tongue weight once you have that figured out. The closer to the...

view full answer... - Solution to Prevent Damaging Friction Pads of Reese Steadi-Flex Weight Distribution SystemThe solution to preventing the friction pads part # RP58527 from damaging with the spring bar removal tool is the trailer jack like you mentioned. You shouldn't be using the tool to pull the bars down with that much tension. It's hard to say if and where the limit for using the trailer jack would be but getting the jack high enough to remove the tension is what you need to do.

view full answer... - Comparing Reese Steadi-Flex to Equal-i-zer Weight Distribution HitchI recommend the Equal-i-zer Weight Distribution # EQ37100ET over the Reese Steadi-Flex Weight Distribution System # RP66559. They both require no drilling to your trailer frame and use the weight distribution bars to keep your trailer moving in a straight line. The Equal-i-zer being made in the USA is a big perk but I also do not like that the Reese uses Friction Pads # RP58527 on their sway brackets to reduce sway. While these are made of a similar material to brake pads they must be replaced...

view full answer... - Quieter Weight Distribution Hitch With Sway Control For a Shasta 25RS Travel TrailerYes, the Reese Steadi-Flex Weight Distribution System 10,000LB # RP66559 and 12,000LB # RP66560 are both good hitches. These both fit within your tongue weight and overall camper weight. You can backup with these hitches installed as well, so you can select whichever you wish but remember if you decide to upgrade your camper you may prefer the 12,000LB option. They do provide a slightly quieter ride as they do use the friction material as opposed to direct steel on steel friction. You...

view full answer... - Why are Weight Distribution Systems so NoisyDue to the amount of tension in a weight distribution system and the fact the components have to move around under that tension there will always be a bit of noise with any system. Now the friction sway control units have even more noise since they parts are rubbing on each other intentionally under that same tension. This creates even more noise. And unfortunately any attempts to remove some of that tension like lubrication or slicker materials will just make the sway control less effective....

view full answer... - Recommended Weight Distribution System With Best Sway Control PropertiesWith the loaded tongue weight of both your trailers being at or around 900 pounds, the Curt # C17500 is getting a little close to the max capacity. The weight capacity of the Equal-i-zer # EQ37120ET is better, but you are pretty close to the minimum capacity with the enclosed trailer. And I do agree this is quite the price difference. With that being said, I am actually going to recommend a completely different weight distribution system. The Reese Steadi-Flex Weight Distribution System...

view full answer... - Does Reese Offer Replacement Spring Bars For The 14K Reese Steadi-Flex Weight Distribution System?Currently Reese only offers the Friction Pad Kit # RP58527 for replacement parts on the 14K Reese Steadi-Flex Weight Distribution System 66561. You will need to get a whole new hitch to get the spring bars.

view full answer...

Do you have a question about this Accessories and Part?

Info for this part was:

At etrailer.com we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Ron M.

2/5/2020

Work as advertised