Replacement Bearing Kit for Fulton F2 Swing-Up Jacks

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.

- All Info

- Reviews (47)

- Q & A (0)

- Videos (1)

- Photos

Fulton Accessories and Parts

- Camper Jacks

- Trailer Jack

- Hardware

- Bearings

- Fulton

Replacement bearings fit Fulton F2-series swing-up jacks.

Features:

- Designed for use with Fulton F2-series swing-up jacks

- Inner diameter of bearing: 0.500"

- Outer diameter of bearing: 0.998"

- Includes 2 washers

500137 Fulton Bearing Replacement Kit for F2 Marine and Recreational Jacks

California residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Video Transcript for Fulton F2 Jacks Replacement Gear Kit Installation

Today we're going to be taking a look at the rebuild process for the Fulton Reem F2 Series or XLT series jack with the 1500 pound capacity. Few of the replacement parts we have available are going to be 1, the top cap. These can sometimes get damaged and it's a really good idea to make sure that you have a good quality 1 on there so dirt, debris, stuff like that's not going to get inside the jack and cause issues. The cap's part number is F500324. Underneath our cap, we're going to find our gear kit in there. The gear kit is going to be what actually drives that jack up and down. Comes with all the hardware and the pins that we're going to need to do the replacement.

That part number's going to be F500314. Below that, we'll have our bearing kit in there. That part number's going to be F500137. This is going to be what helps reduce any of the friction, so we don't have metal on metal contact, and again, hardware there. Also, the replacement handle. If your handle's been damaged, something that's very easily replaceable. Part number on that is F500134. Now, these few simple components can be used to completely rebuild your jack, so you don't have to replace it with a brand new 1.

This is going to give us a very easy solution to just keep all those components that don't really wear and tear and be able to rebuild it. Basically have a brand new jack when we get done. We're going to set our parts over to the side here. Give us some room to work on the jack. First thing we're going to do is remove the cap located here on the top. You can use either a quarter inch bit driver or a flat head screwdriver.

You just want to remove the small self inaudible 00:01:41 screw. Not a lot to it there. I'm just pushing in slightly and out. Then that should allow us to lift that up off of the grease there, although sometimes it does kind of grab a hold of it there. Just lift that up and off. Of course, at that point, you just replace your new 1 if that's all you we're doing.

The larger hole is the 1 you'll use to slide down over the greasesert 00:02:09 and then just tip the top in. Replace your screw. Pretty straight forward there. This here, this is a fairly new jack and you'll see that Marine grade grease that they have in there. When doing your rebuild, you do want to ensure that you do have Marine grade grease available, that way you can replace it with the same. We don't want to put something in there that might not have the water resistance we're looking for. I'm going to get this cleaned off here. As we clean it, what we're looking for is going to be that little dimple that's in our gear. Same thing here. That's where our pin rests. Rests right through there, so we'll take a punch and a hammer. This is a 3/16 punch. Tends to work out pretty well to be the right size. We'll just use our punch and our hammer. We want to drive that pin through. Now, we'll have a little bit of room we can do it straight on, but there in a minute, we'll have to turn it sideways slightly so we drive it out on an angle. Again, once we get it started there, kind of turn it to where it's slightly angled and continue tapping it out. Pull our punch out. Once that pin's out, we should be able to just lift straight up on that handle. Now, when you go that, that gear's going to want to fall out as will as the little spacer bushing that fits of the outside, so set those aside. Now, we've got our base gear and keep in mind both our gears are the same. 1 just sits on the bottom and 1 sits on the side there. We get that pulled out. Then, if we'll look in the tube, you see the top of our screws right there. There's a pin that passes through it. Now, this just sits in there. It's not in there with any pressure or anything. We want to get that pulled out. We'll stand our jack up. We're going to lift that straight up and off there. We slide the outer tube off of the inner tube there. Now, when we do that, there's going to be this little plate in here. Watch for that. Sometimes it likes to come out of there, and on top of that's going to be 1 of the washers. That's going to be the washer that comes with the gear kit right here. The thicker black washer. Pull that off of there. We can pull that plate out and you'll see it's just a hollow tube. Not a lot to them. Just put that back in there and look at our bearing kit real quick. See our bearing This is just going to sit down on top of that screw. Just going to pull off there. 1 is that larger thrust washer which also comes with the new bearing kit. At this point, we're ready to put it back together. Take the thrust washer of our new bearing kit. We'll take our new bearing. Slide that down on. Now, we just need to get 2 sections of our jack put back together. Now, as we put the 2 of these together, we just want to ensure that that small raised, look at that, rounded hump rides right down in the groove that's here on the inner tube. Then once we've got that in place, it should slide nice and freely. If we just want to bring that screw portion right up through that plate. Now we can take the flat washer that we removed. We're going to slide that back on. We've got the shorter, larger diameter pin that's going to slide into our top of our screw, there. Just like that. Now, of course, we're going to reuse the gears that came out since it's a brand new jack, but you'll be putting in new gears. We just want to make sure the enclosed little groove in there goes right down on top of that pin. You'll know it's seated properly because that screw's going to be almost flush with the top of the gear. First we'll put our bushing in. Outside edge there. We'll take our gear. We're going to position that so that the teeth of this gear mesh with the teeth of that gear. We'll just hold that as we slide it through. Need that to come through. All the way through the other side there. Now we need to rotate our gear kit slightly here to where we have that little indention facing us. We'll pull our handle out so that the hole in the handle lines up with that indention. Now we'll take our small pin there. Line that up with the hole in our handle and get it tapped back into position. Just check for good, smooth operation. You'll see that our pin is a little bit off center, so just want to make sure we get it about equal sides coming out on both sides there. All right. Looks good. We just want to take your marine grease and put a little bit more in there. We left some, but it's never going to hurt. Can't overgease the jack. All right. That should be more than enough there. We just want to get our cap put back on there. Reusing that same little self inaudible 00:08:13 here. That same set screw that we have before. We'll be ready to put our jack back to good use. We hope you find this video helpful in showing that with a few simple parts, you can rebuild your jack rather than doing a complete replacement.

Customer Satisfaction Score:

99% were satisfied with this product

1% of customers were not satisfied

- Wrong item was ordered

- Product did not meet expectations

Customer Reviews

Replacement Bearing Kit for Fulton F2 Swing-Up Jacks - F500137

Average Customer Rating: 4.9 out of 5 stars (47 Customer Reviews)

Replacement bearings fit Fulton F2-series swing-up jacks.Kit was exact replacement. Price was excellent. Was very easy to install. One pic is of all I could find of old bearing and other is jack installed.

Used this .5" bearing to fix my USA made Shelby trailer jack (NLA). Works great. Made in Mexico which is usually better quality than chinesium alloy. Lubed it up with Redline marine grease and I'm back to cranking with ease!

I'm glad I chose etrailer to order my bearing kit to repair my Fulton trailer jack! After many years of use and sitting outside all these years, it started to work hard and started to squeak when it was turned! The bearing and spacing washers fit perfectly and now it works as well as the day I bought the jack!! Great product!!!

Robert

10/16/2020

Awesome!! Still working like when it was new!!

The item arrived quickly and installation was very easy. The video they provided was excellent for the installation. Will order from etrailer again.

Martin

8/9/2021

Works Great Good price Easy to install

Due to the tolerance stack up, I only used the thrust bearing. My jack had three flat washers stacked as a bearing. Worked bitchin!

Todd

6/30/2019

Fantastic

Easy to navigate the site to find what I need. Quick order fulfillment and shipping.

William

10/2/2022

The replacement parts are working as intended. The biggest issue is how the part was designed. The trailer is always stored indoors and I took some extra care and grease during reassembly to prevent a repeat failure. If the trailer was stored outdoors, I would bet good money the part would ultimately fail again. I considered installing a sealed thrust bearing that would allow easier operation and last longer. But how much I use the jack didn’t justify the expense or the trouble to source one. Same would be true for an OEM install I imagine.

After removal of the gears, the bearing assembly replacement is easy. I repacked the bearing with waterproof grease, salt water envirement. Too bad this bearing is not stainless steel and sealed !, it should be !!!!, along with the washers and pins, after all there is a limited lifetime warranty - but I had to pay for the parts!!!

I have not used the part as of yet. Due to the fact that the old tongue jack was not fixable total rust case. I bought a new jack but now I do have a spare handle.. I am sure someday I will use them never hurts to have spare parts you just do not know when you mat need them.

Great service from etrailer. But the Fulton F2 trailer jack needs to be upgraded to better bearings and hardware. The existing bearings stand no chance against salt water environment and barely lasts 6 months. Stainless steel hardware and closed roller bearings should make it so much more durable.

I bought this kit as a spare because this is one of the things that will

need to be replaced on the Fulton F2 Trailer Jack under Salt water conditions. It looks like OEM quality and was delivered in about 10 days, normal delivery. Slow if you need it right away you will need to pay the extra delivery charges.

I had to replace the trust bearing assembly on my Fulton F2 trailer jack. Obviously this is a difficult item to find. After doing a lot of searching on-line, I found exactly what I needed on etrailer.com.

The ordering process and delivery was trouble free and the item was delivered when expected.

Great price with great service - what more could you want?

If you are rebuilding the F2 jack the bearings are an essential part to replace. The bearings in my jack were completely destroyed. as for the gears, they were chewed up and needed replacing. Fulton should be making a gear box housing. This was what had broken on my jack and other people had the same problem. If this gearbox breaks the jack is useless. Unfortunately, it took a bit of research to find out they don't sell a replacement gearbox. Essentially I had to rebuild it with epoxy and pex plumbing tube. Time will tell on the fix. So far so good!

I had no luck trying to find this bearing kit locally. My online search showed that Etrailer stocked the item I was looking for. I spoke with a reprentative on the phone to help me identify the proper part. While we were on the phone she sent me an image of the bearing kit so I could confirm. I ordered the part online. The part arrived sooner than expected and was the correct part. For this particular order the process of identifying the part, shipping, and installing the part was text book. The way that it should be.

Thank you Etrailer.

Shawn W.

Very satisfied with this product. It was priced right, and delivered promptly to my door. Installation of the bearing and gear set was a snap and the jack is good as new now. I recommend this vendor for all your trailer part needs.

My jack started getting extremely tuff to crank up and down. This kit rebuilds all the internals and was a pretty simple repair. Watch the [online] video on the rebuild. Simple and affordable.

This is the second time I have bought parts from etrailer.com. The price was fair, the web site is easy to navigate and the parts came quickly. I will use this site again!

Alex T. was very helpful in determining the correct bearing for my old obsolete Trailer jack. Delivery was swift and the repair was quick. Thank you!

The parts were easy to locate and confirm on the site using their "search" tool. I received exactly what I ordered and had confirmation it was shipped that same day. The parts were exactly what they claimed and are working perfectly. I continue to have nothing but positive experiences from etrailer. ~ Thank You

Instructions were very helpful and made the repair process go smoothly!

Installed bearing kit and now it works like new !

Jack part - gear set is slightly larger than original gears. Some machining made it work. My jack is operational again. Thanks

Shipped quick, arrived on time. Would order from etrailer again.

easy process! had what I needed, fast shipping and video on website for most products showing how to install.

Right part made in USA, quick delivery, excellent service!

See what our Experts say about this Fulton Accessories and Parts

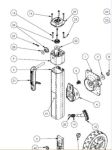

- Is a Replacement Gear Housing Available for the Fulton F2 Swing-Up, Wide-Track Trailer Jack?No, Sheldon I am sorry we do not. Additionally, I checked with Fulton and they do not offer what is labeled part number 9 on the exploded diagram listed below. If you need to replace this part you will most likely have to purchase a new Fulton F2 Swing-Up, Wide-Track Trailer Jack item # F1413040134.

view full answer...

Info for this part was:

At etrailer.com we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Albert P.

5/8/2018

Still working fine. I am well pleased with it.