Testing Trailer Brakes that are Getting Weak on a 8-1/2 X 24 Foot Cargo Trailer

Question:

I have a 8.5x24 cargo trailer that I use for my construction company. The brakes are getting weak. I have my brake activator turned all the way up and when i hit the brakes I can barely feel the trailer brakes kick in. Is that normal? If I need to change them, what would be my best choice? I would rather have more brakes than not enough. Thanks.

asked by: Jerry C

Expert Reply:

It sounds like the magnets are getting worn and are not supplying the enough force to the brake assembly when the brakes are applied. The first thing I would do is use a voltage tester and check the brake output wire on the trailer while someone uses the manual knob in the cab. If you are not getting full power, you will need to test the brake controller for proper function.

If you are getting full power with the manual slide fully engaged, then you will need to remove the hub and check the brake magnets, brake shoes, and associated parts. If the magnets are wearing oddly, or the windings are showing then you will need to replace them (see link). If there are no signs of wear, then you will need to test them to make sure they are still good.

To test the Brake magnets with an ammeter you would connect the ammeter between the positive terminal of a battery and one of the magnet wires, then connect the other magnet wire to the negative battery terminal. Check the amperage, and if it is greater than the specified amount (see chart below), replace the magnet. If the reading is less than the specified amount, then the leads are bad and should be replaced.

Electromagnet Specifications

7 inch Diameter Brake Drum

Max Amps at 9-10.5 Volts Max Amps at 12-13 Volts

2 Brakes 4.7-5.6 6.3-6.8

4 Brakes 9.5-11 12.6-13.7

6 Brakes 14.3-16 19.0-20.6

10 and 12 Inch Brake Drums

Max Amps at 9-10.5 Volts Max Amps at 12-13 Volts

2 Brakes 5.6-6.6 7.5-8.2

4 Brakes 11.3-13.3 15.0-16.3

6 Brakes 17.0-20.0 22.6-24.5

Next disconnect the negative wire from the brake magnet wire and connect it to the base, housing, of the brake magnet. If there is any amperage the magnet is shorted and will need to be replaced.

Finally, using an ohmmeter check the resistance between the brake magnet wires. If the resistance is not within the the specified range (see below) then the magnet will need to be replaced.

7 inch brake magnet resistance should be 3.8-4.0 Ohms

10 and 12 inch brake magnets resistance should be 3.2-3.5 Ohms

You should also check the brake pads for wear. Another good idea would be to grease the trailer bearings while you have things apart. We also offer grease and parts to complete this maintenance(see links).

Product Page this Question was Asked From

Electric Trailer Brake Assembly - Self-Adjusting - 10" - Left Hand - 3,500 lbs

- Accessories and Parts

- Trailer Brakes

- Electric Drum Brakes

- LH

- 3500 lbs

- Brake Assembly

- Self Adjust

- 10 x 2-1/4 Inch Drum

- etrailer

more information >

Featured Help Information

Miscellaneous Media

Continue Researching

- Shop: Brake Controller

- Video: etrailer Electric Trailer Brake Kit Installation

- Shop: Seaflo Battery Disconnect Switch for Boats and RVs - On/Off - 900 Amps

- Article: Testing Trailer Brake Magnets for Proper Function

- Article: Brake Controller Installation: Starting from Scratch

- Article: Installing an Electric Brake Controller on 2007-2013 GM Full-Size Truck or 2007-Present GM SUV

- Search Results: replacement trailer brake magnet

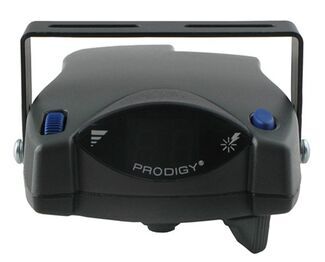

- Q&A: How to Install a Prodigy P3 Brake Controller in a Vehicle with a 24 Volt System

- Q&A: Can the Tekonsha P3 Trailer Brake Controller be Reset

- Shop: Trailer Hub and Drum Assembly - 3,500-lb Axles - 10" Diameter - 5 on 4-1/2 - Pre-Greased

- Shop: etrailer Electric Trailer Brakes - Self-Adjusting - 10" - Left/Right Hand Assemblies - 3.5K

- Shop: etrailer Electric Trailer Brakes - 10" - Left/Right Hand Assemblies - 3,500 lbs

- Shop: Electric Trailer Brake Assembly - Self-Adjusting - 10" - Left Hand - 3,500 lbs

- Shop: Replacement Magnet Kit for 10" Electric Trailer Brake Assemblies - 3,500 lbs

- Shop: Electric Trailer Brake Assembly - Self-Adjusting - 10" - Right Hand - 3,500 lbs

- Search Results: 12 volt battery disconnect switch

- Search Results: transmission cooler hoses

- Search Results: disconnect switch

- Search Results: battery quick disconnect

- Search Results: battery disconnect switch

- Search Results: battery switch

- Shop: Windshield Wiper Blades

- Q&A: How Many Batteries Needed for Go Power Industrial Pure Sine Wave Inverter

- Q&A: Powering A Freezer On A Trailer While Traveling

- Q&A: What Size Battery Bank for a 2000 Watt Invertor

- Q&A: Parts Needed to Add 30 Amp Shore Power and Solar Panels to Cargo Trailer

- Q&A: What Options Are There For Operating A Refrigerator In RV While Driving?

- Shop: Trailer Hitch

- Article: Determining Trailer Tongue Weight

- Video: Review of Seaflo Battery Disconnect 2 Position Switch Boats RVs 48V - SE29VR