When is it Recommended To Use Dielectric Grease When Wiring

Question:

I just purchased replacement lights for my boat trailer from you and getting my wiring supplies ready. I am going to run fresh wires throughout including a ground wire. I watched your video where the dielectric grease was put in the plug connector but none was used in the butt splice. I am planning to use the 3M inline scotchlok splice connectors. Is using grease on these connectors and butt splices recommended? What about heat shrink tubing? Excited to get my new LED lights all hooked up but want them to last.

asked by: Wayne N

Expert Reply:

We want to thank you for your recent purchase!

You wouldn't need to use dielectric grease with a butt connector such as part # DW05714 (view video at the 1:16 mark) as electrical tape will work great.

Heat shrinkable tubing such as part # DW05451 will help protect against the elements. It works with 14-18 gauge wire. Most trailer light wiring is 16-gauge. Once you have your wire inside the tubing you can use a heat gun, blow dryer and/or lighter utilize the heat shrinkable tubing. We also offer heat shrink butt connectors part # DW05744-10. (view 3-wire pigtail video at the :35 mark) Dielectric grease isn't necessary.

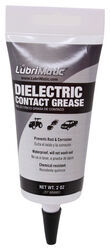

Using dielectric grease with a quick splice wire connector such as part # SWC501915-1 is just fine. A little dab prior to inserting wires in the quick connect gives a corrosion-resistant barrier. You will still use electrical tape around the quick splice for added protection.

I have included FAQ and videos for you as well.

Products Referenced in This Question

Primary Wire Heat-Shrinkable Tubing - 18-14 Gauge - Black - 1/8" Shrink Diameter - 6" Long

- Electrical Tools

- Wire Protection

- Heat Shrink Tubing

- 1/8 Inch Diameter

- 6 Inch Long

- Black

- Deka

more information >

Butt Connector - PVC - for 16-14g Wire - Qty. 1

- Wiring

- Wire Connectors

- Butt Connectors

- 16-14 Gauge

- Deka

more information >

Deka Heat Shrink Butt Connector - 16-14 Gauge - Nylon Insulation - Blue - Qty 10

- Wiring

- Wire Connectors

- Butt Connectors

- 16-14 Gauge

- Deka

more information >

Quick Splices - Self-Stripping Connector - Closed Port - 10-12 Gauge - Yellow - Qty 1

- Wiring

- Wire Connectors

- Quick Splice Connectors

- 12-10 Gauge

- Spectro

more information >

Product Page this Question was Asked From

Dielectric Grease for Electrical Connectors, 2 oz.

- Accessories and Parts

- Trailer Wiring

- Wiring

- Dielectric Grease

- LubriMatic

more information >

Featured Help Information

Miscellaneous Media

Continue Researching

- Shop: Hydrastar Electric Over Hydraulic Actuator for Disc Brakes - 1,600 psi

- Q&A: Is Dielectric Grease Good For Protecting My 4-Pin Trailer Connector?

- Q&A: Where To Attach Blue Wire From 5 Wires on Trailer When Installing a 7-Way Connector

- Shop: Trailer Wiring

- Video: Review of Deka Wiring - 16-14 Gauge Butt Connectors - DW05744-10

- Shop: Curt 5th Wheel/Gooseneck Custom Wiring Harness w/ 7-Pole Connector - 7' Long

- Shop: Brake Controller

- Shop: Pollak 5th Wheel / Gooseneck T-Connector with 7-Pole - Ford, GM, Dodge, Nissan w/ Factory Plug

- Q&A: Parts Needed to Install a Draw Tite Activator Brake Controller in a 2008 Toyota Tundra

- Q&A: What Gauge Wire Is Required On a 7-Way Connector

- Shop: Deka Self-Fusing Auto Tape - Black - 10' Roll - Qty 1

- Shop: Dielectric Grease for Electrical Connectors, 2 oz.

- Shop: Universal Installation Kit for Trailer Brake Controller - 7-Way RV and 4-Way Flat - 10 Gauge Wires

- Shop: Deka Heat Shrink Butt Connector - 16-14 Gauge - Nylon Insulation - Blue - Qty 10

- Video: Curt 5th Wheel Wiring Harness Installation - 2021 Ram 2500

- Search Results: grease

- Search Results: wiring

- Search Results: dielectric

- Search Results: silicon

- Search Results: butt connector

- Search Results: connectors and fittings

- Search Results: electrical tape

- Q&A: Can Weight Distribution System Be Used on Aluminum Trailer Frame

- Article: Dielectric Grease Review

- Video: Curt 5th Wheel Wiring Harness Installation - 2016 Ram 2500

- Q&A: What is Correct Gauge of Wire for Wiring Trailer Brakes

- Q&A: How Tight Should the Nuts be When Attaching a Trailer Brake Assembly to a Trailer

- Article: Testing Trailer Brake Magnets for Proper Function

- Article: Trailer Wiring Diagrams

- Shop: Trailer Hitch