Testing a Tandem Axle Trailer With Only 1 Brake Assembly Working

Question:

Hi there, Ive got a tandem flatdeck trailer with Dexter brake assemblies all around. During a recent routine check of my braking system I found that only 1 hub had any braking. Upon further checking I found that the hub that was braking Was the only hub that made any humming sound when the brakes were activated From the truck. This leads me to believe the problem is electrical. Where do I go from here? Also, When Im testing the magnets on these Dexter assemblies do I slide the magnet off of the spring-loaded rail to remove the wires for the different tests Ive read about? Thanks for the time. I look forward to yiur reply. Regards

asked by: Barry

Expert Reply:

Since power is reaching one of your brake assemblies, the issue could be caused by a number of other factors such as poor ground connections, brakes need to be adjusted, the electric brake circuit, or bad brake magnets.

The first step I would take is to inspect the ground connections for the trailer connector and each brake magnet. If the grounds for the brake magnets are all spliced together, I recommend ground each of them to the trailer frame individually. Be sure they are grounded to a clean, bare metal surface on the frame. I also recommend checking the adjustment of your brakes. Sometimes the magnets are working, but you cannot always hear them hum. When you spin each wheel on the trailer, you should hear a slight drag coming from the drum.

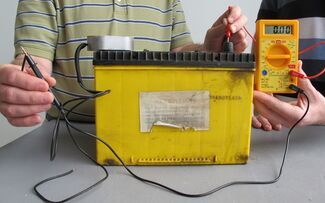

If the ground connections look good and the brakes are adjusted properly, take a look at the electric brake wire. Look for any loose connections or damaged sections of the wire that could cause a drop or loss of power. To ensure power is reaching each of the brake assemblies, use a circuit tester, like part # PTW2993, or a multimeter, like part # PT89ZR, and test the electric brake wire just before it enters the brake assemblies. To power the brake circuit, you can hook up to your truck and use the manual override on your brake controller or you can use an independent 12-volt power source such as a vehicle battery. If you use your brake controller, make sure the power is set to the maximum power level.

If you are still having a problem after determining the wiring is in order, we will want to test the brake magnets. The first test is a visual inspection. If you see the copper windings on the face of the magnet or excessive wear after you remove the hub, then that is a good indication that the magnets need to be replaced.

The next step would be to test the brakes with a multimeter. I have attached an FAQ article on testing brake magnets for you to check out. You can test all 4 brake magnets without removing them from the brake assemblies by following the first part of the FAQ. The max amps at 12-13 volts for 4 brakes TOTAL should be 15-16.3 amps on 12-inch brake assemblies. This first section explains the process for testing all of the magnets at once.

If you want to test each magnet individually, you can slide the magnets off of the spring-loaded rail. They are held in with a single metal clip. You should get 3.2-4 amps at 12-13 volts per magnet.

If you are testing for resistance for an individual magnet, you will be looking for 3-3.8 Ohms per magnet for a 12-inch assembly.

If you determine the magnets are bad and must be replaced, you can use part # BP01-225. This magnet fits 12-inch Dexter brake assemblies for 6,000 lb axles.

Products Referenced in This Question

Replacement Trailer Brake Magnet for Dexter Electric Brake Assemblies

- Accessories and Parts

- Trailer Brakes

- Electric Drum Brakes

- 4400 lbs

- Brake Magnets

- 10 x 2-1/4 Inch

- Dexter

more information >

Digital Multimeter with 42" Long Test Leads - LED Display

- Electrical Tools

- Testers

- Multimeter

- Yellow

- Performance Tool

more information >

Product Page this Question was Asked From

Dexter Electric Trailer Brake Assembly - 12" - Left Hand - 6,000 lbs

- Accessories and Parts

- Trailer Brakes

- Electric Drum Brakes

- LH

- 6000 lbs

- Brake Assembly

- Manual Adjust

- 12 x 2 Inch Drum

- Dexter

more information >

Featured Help Information

Instructions

Miscellaneous Media

Continue Researching

- Q&A: Is 2 Inch Hitch Ball Okay to Use With 2-5/16 Inch Coupler

- Q&A: One Side of Trailer Brakes Work But Other Side Does Not But Uses Same Wire

- Search Results: 3500 lb axle with brakes

- Shop: etrailer Electric Trailer Brakes - Self-Adjusting - 10" - Left/Right Hand Assemblies - 3.5K

- Shop: etrailer Electric Trailer Brakes - 10" - Left/Right Hand Assemblies - 3,500 lbs

- Q&A: When Do Brakes Need to be Added to Both Axles of Tandem Axle Trailer

- Q&A: Can Brakes be Installed on Only One of the Axles of a Tandem Axle Trailer

- Shop: Dutton-Lainson Hand Winch - TUFFPLATE Finish - 2 Speed - Direct Drive - 2,500 lbs

- Shop: Trailer Hub and Drum Assembly - 3,500-lb Axles - 10" Diameter - 5 on 5-1/2 - Pre-Greased

- Article: Most Popular Wheel Bearings

- Q&A: Lug Nut Torque Chart for Trailer Wheels

- Search Results: 25580

- Video: etrailer Electric Trailer Brake Kit Installation

- Shop: Trailer Hitch

- Q&A: How to Measure to Determine the Size Trailer Brakes Needed For Hydraulic Drum Replacement

- Shop: etrailer Electric Trailer Brakes - Self-Adjusting - 12" - Left/Right Hand - 5.2K to 7K

- Article: Trailer Wiring Diagrams

- Shop: Trailer Wiring

- Search Results: trailer brakes

- Shop: Dexter Electric Trailer Brakes - 10" - Left/Right Hand Assemblies - 3.5K

- Video: etrailer Trailer Brakes - Electric Drum Brakes - AKEBRK-35-SA Review

- Q&A: Replacement Drum Brake Actuator for a 1995 4 Winns Model 3916 Trailer

- Shop: Brake Controller

- Search Results: l44649

- Article: Parts Needed to Add Electric Drum Brakes to a Trailer

- Shop: Gooseneck Hitch

- Search Results: 10~36

- Shop: Easy Grease Trailer Hub and Drum Assembly for 3.5K Axles - 10" - 5 on 4-1/2 - Pre-Greased

- Article: Testing Trailer Brake Magnets for Proper Function

- Article: Trailer Tire Sizing