How to Install a Weight Distribution Hitch (With Pictures & Video)

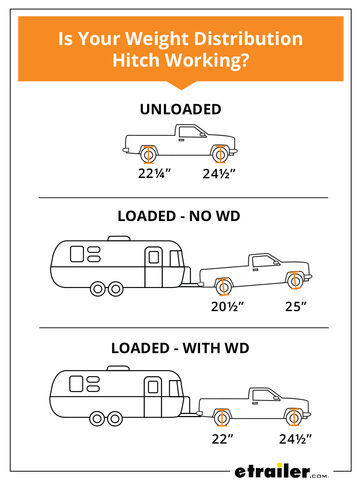

Step 1: Take Vehicle Measurements

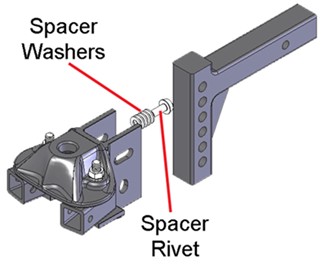

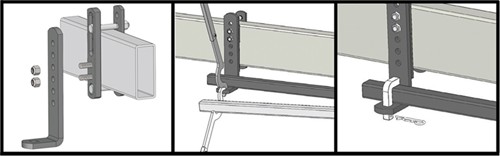

Step 2: Install the Weight Distribution Shank

Step 3: Install the Hitch Ball

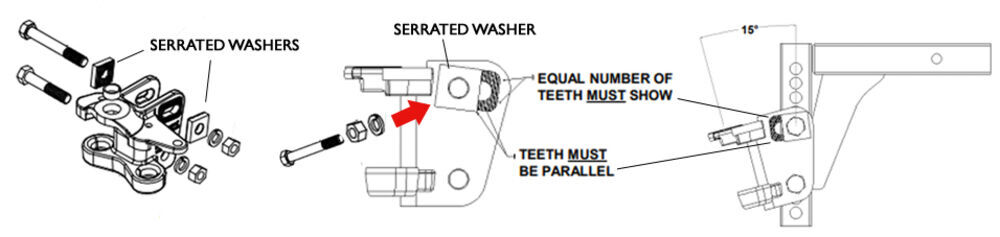

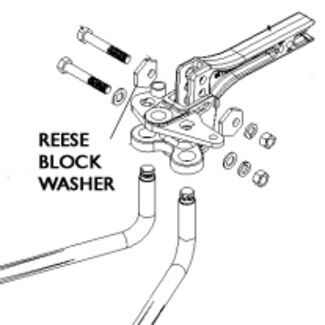

Step 4: Install/Adjust the Head Assembly

Traditional Washer Style

Serrated Washer Style

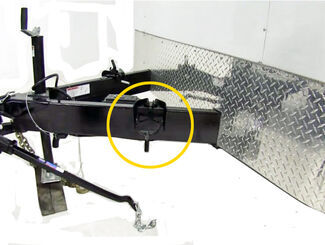

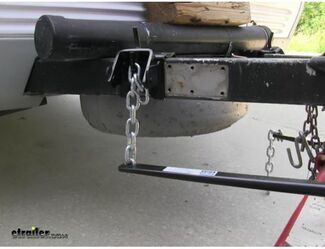

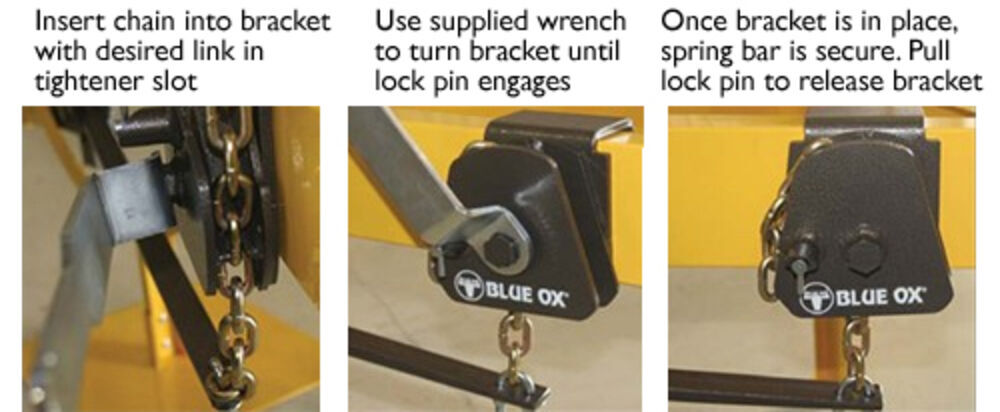

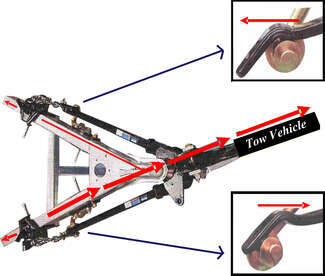

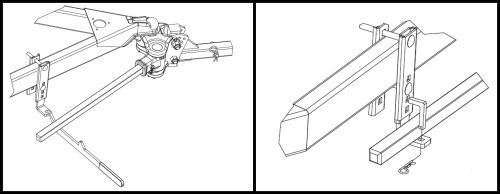

Step 5: Connect Spring Arms and Sway Control

Chain and Bracket Systems

Step 6. Check Your Work

Terry T.

1/11/2022

I have a 2020 Ford F250 and I am trying to set up my EAZ Lift Trekker but I think I need a shank with a longer drop. With the hitch mounted in the lowest position on the included shank, the top of the ball is at 24". The top of the trailer hitch coupler is at 20". The truck when unloaded at the wheel wells measures 41.25" on the front and 43.75" at the rear. Do I need an extra-long drop-shank or just hitch up the trailer and try to level out the squat by using the weight distribution? Thanks!

Francisco

8/8/2021

9.5 front with trailer Rear 9 with trailer 9.5 empty front 10.5 empty rear Is this ok or do I need to adjust. Thanks for the info.

Richard C.

7/9/2021

My 2017 ram 1500 hemi sits 2 inches lower in the front than rear,,dealer says this is normal..Now with equalizer hitch 7000 lb. trailer tonque weight 610 lbs. chains in 3rd link the front is 1/2 inch higher the rear is 2 inches lower .truck looks level,but the trailer is 2 inches lower in the front than the rear...Is this right or how can i fix it?

Richard C.

7/9/2021

2017 ram 1500 short box when sitting empty front measure 34 1/4 in. rear 36 1/4 rear is 2 inches higher than the front the dealer says it suppose to be..

Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"Very helpful/friendly Customer Service. Competitive Pricing. Shipping was Fast."

Popular Vehicles

- Subaru Forester

- Ford F-350 Super Duty

- Ford F-250 Super Duty

- Chevrolet Silverado 1500

- Jeep Wrangler Unlimited

- Jeep Wrangler

- Ram 3500

- Toyota Highlander

- Ram 2500

- Chevrolet Silverado 2500

- Subaru Outback Wagon

- Chevrolet Silverado

- Dodge Ram Pickup

- GMC Sierra 2500

- Ram 1500

- Ford F-250 and F-350 Super Duty

- Jeep Grand Cherokee

- Toyota Tacoma

- GMC Sierra 3500

- Toyota Tundra

- Ford Escape

- More >>

Christopher H.

7/23/2022

I have a 2022 Silverado 1500 ZR2 (factory 2" lift) and a 2022 Cougar 25RDS (approx. 7k pounds loaded). When I setup my e2 (10k pound) wdh I can get my front measurements exactly back to unloaded +/- 1/8" easily but the rear of the truck sags about 3.5". What would you recommend to lift the rear back up? The ride is extremely rough and the nose of the truck feels extremely lite. This is the 3rd camper and 4th truck I've put this system on and this is the first time I've been unable get get it properly adjusted. I'm willing to put airbags or sumo-springs on the truck but would prefer to leave it factory so not to lose my daily unloaded driving ride.