How to Bleed Your Trailer Surge Brakes

Can you bleed your trailer brakes by yourself?

How to Bleed Surge Brakes

Fill Master Cylinder with Brake Fluid Bleed Master Cylinder Install Bleeder Hose on Valve Bleed Brake Furthest from Master Cylinder Repeat Bleeding Process on Remaining Brakes Fill Reservoir with Brake Fluid

Do not look directly into the reservoir while pumping the push rod as fluid can squirt up and get in your face. Just don't do it. Do not allow brake fluid to contact any painted surface as it will damage the finish. To protect your backing plate assemblies from corroding should you get brake fluid on them, we recommend first spraying them down with a rust-resistant spray before you start this process. Do not reuse brake fluid—it may contain contaminants. Trust me, reusing brake fluid won't save you any money. Never let the reservoir fall below 1/2 full during the bleeding process—air can get sucked in and you will have to start all over.

Step 1: Fill Master Cylinder with Brake Fluid

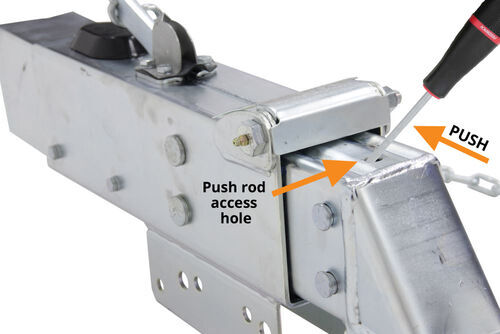

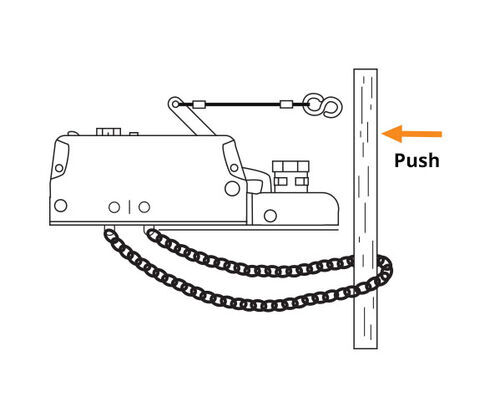

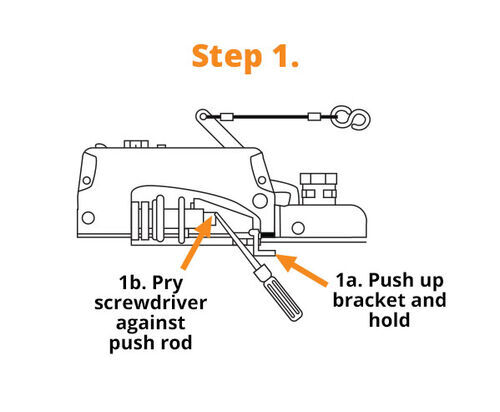

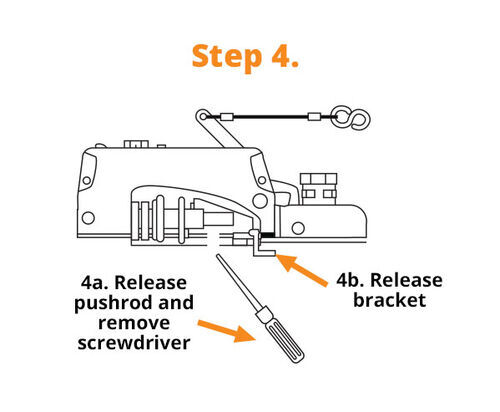

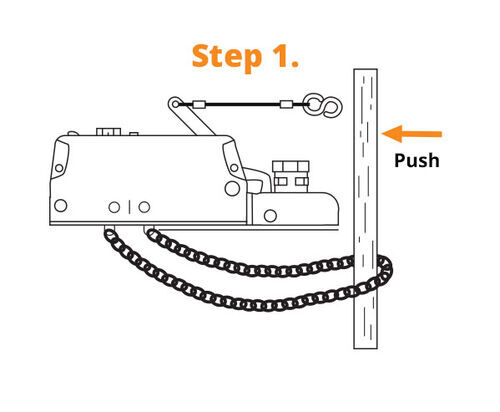

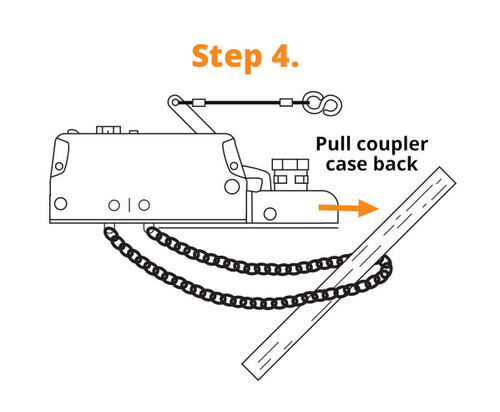

Step 2: Bleed Master Cylinder

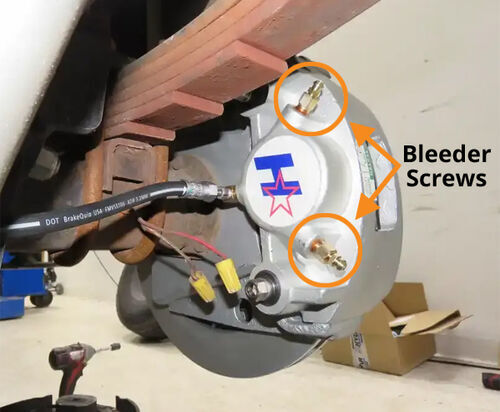

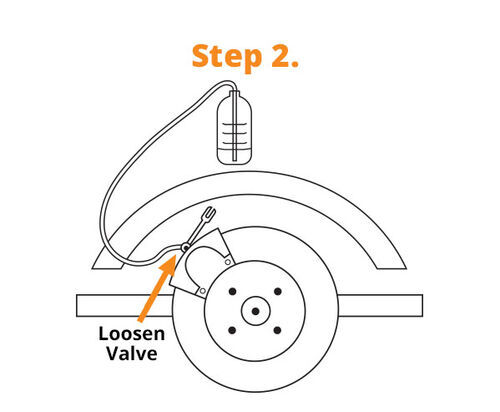

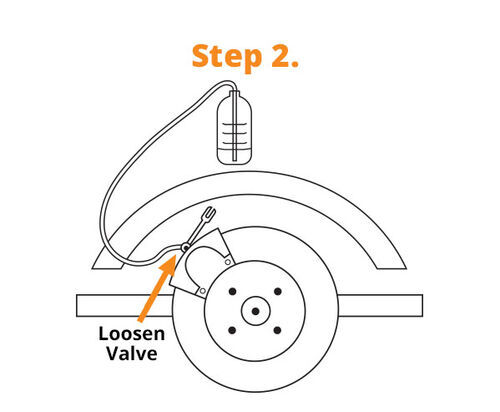

Step 3: Install Bleeder Hose on Valve

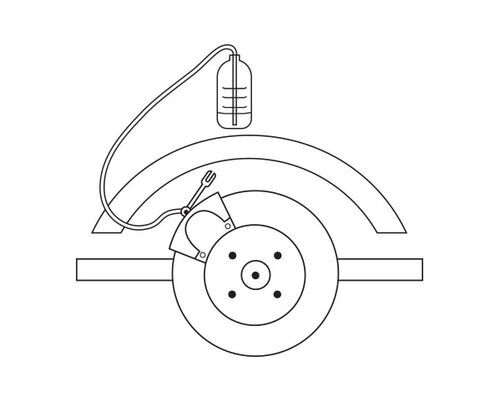

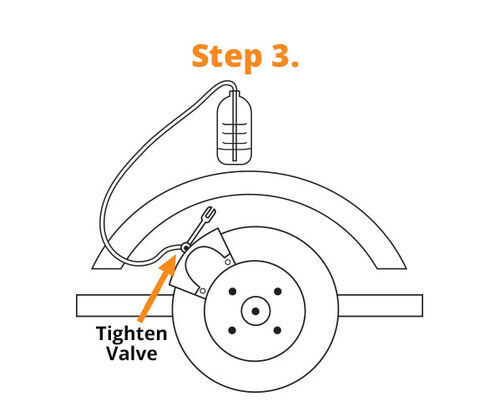

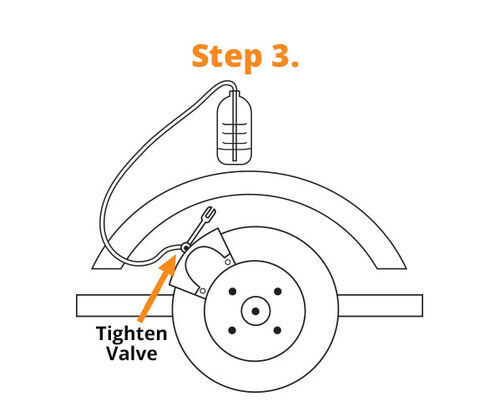

Step 4: Bleed Brake Farthest from Master Cylinder

AKA Grab Your Neighbor and Get to Work

Step 5: Repeat Bleeding Process on Remaining Brakes

Step 6: Fill Reservoir with Brake Fluid

Dirk

8/5/2023

I have a Demco hydraulic surge drum brake coupler. There are two bolts on there that have a decal that says do not adjust. How do I make sure that are tightened at the right amount ? I am guessing too tight and the coupler will not be able to slide when brakes are applied , nor release when I pull away . Advice appreciated. Thank you

Joe M.

10/31/2021

Does this process work for a trailer with drum brakes? I am changing out the old actuator with new one.

Tj B.

1/5/2021

How do i put the hitch back into the trailer. the hitch and the coupling came loose. I have the hitch, but im wondering if i just bleed the hose goes into the master cycllnder. can you explain this for me.

Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

Popular Vehicles

- Subaru Forester

- Ford F-350 Super Duty

- Ford F-250 Super Duty

- Chevrolet Silverado 1500

- Jeep Wrangler Unlimited

- Jeep Wrangler

- Ram 3500

- Toyota Highlander

- Ram 2500

- Chevrolet Silverado 2500

- Subaru Outback Wagon

- Chevrolet Silverado

- Dodge Ram Pickup

- GMC Sierra 2500

- Ram 1500

- Ford F-250 and F-350 Super Duty

- Jeep Grand Cherokee

- Toyota Tacoma

- GMC Sierra 3500

- Toyota Tundra

- Ford Escape

- More >>

Bill

2/1/2024

Hello. I have done full system brake bleeds replacing the entire fluid from the master cylinder and lines on cars before with a 1 person suction system with a fluid bottle placed on the bleed valve. Makes it really simple to completely replace all brake fluid in the system. Considering this, I have a dual axle trailer. Is there some reason i can not do this same process on the trailer while just filling the brake reservoir each time new fluid is sucked through the lines? I was actually surprised you did not have this option outlined in the article as well since it can be done with one person if done carefully. Please let me know. Thank you.