Double-Eye Trailer Suspension System Review

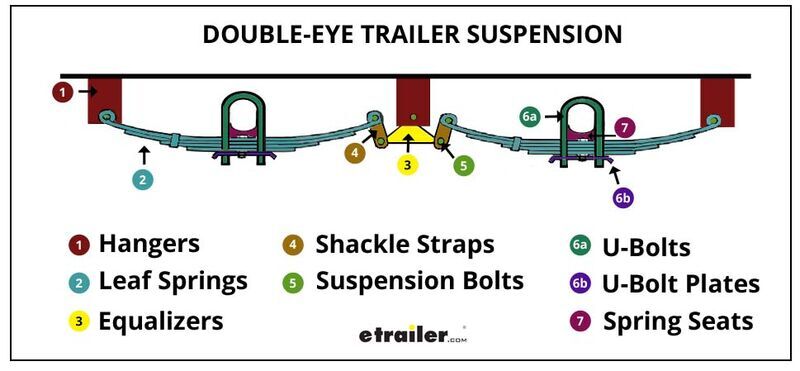

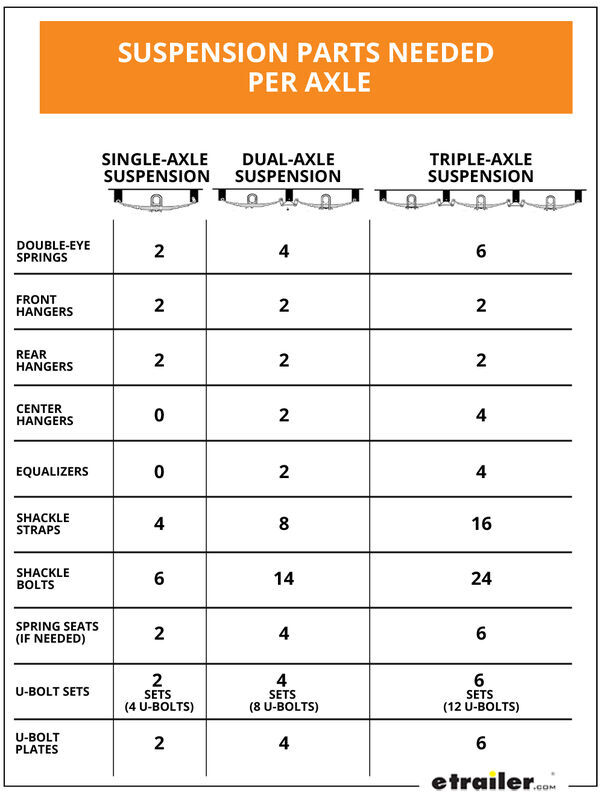

Double-Eye Trailer Suspension Components

Hangers Leaf springs Equalizers Shackle straps Suspension bolts U-Bolts/U-bolt plates Spring seats

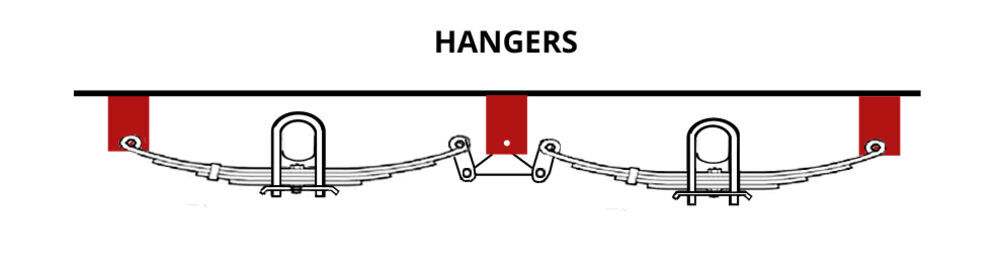

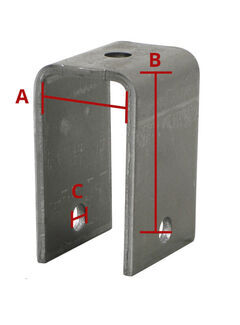

Hangers

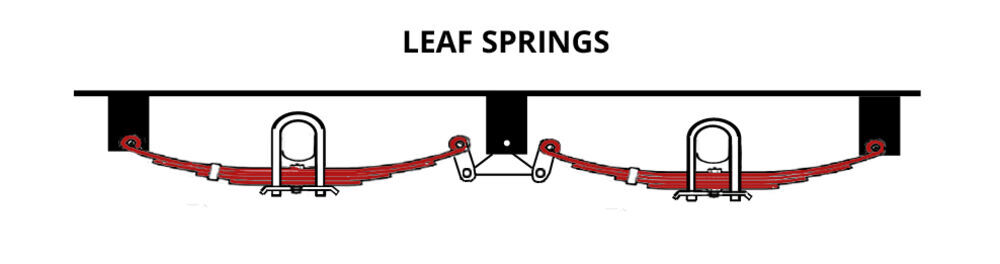

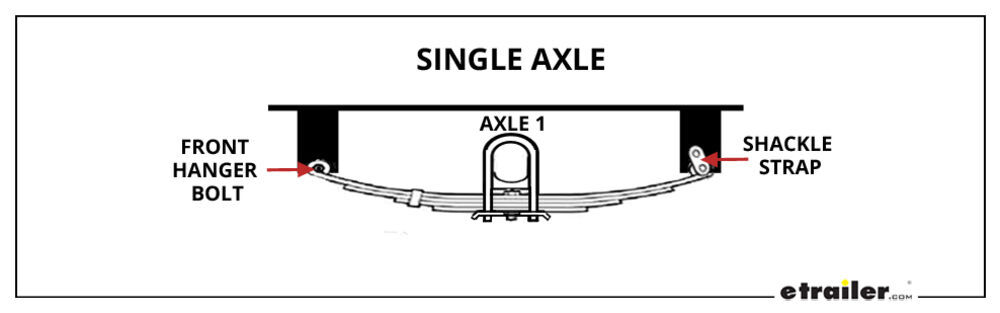

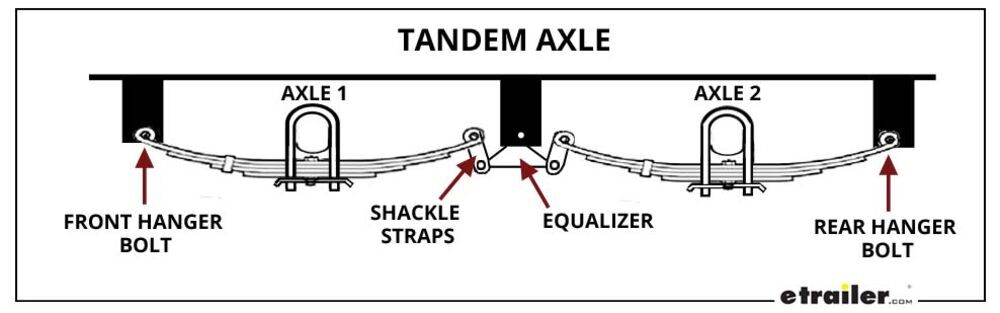

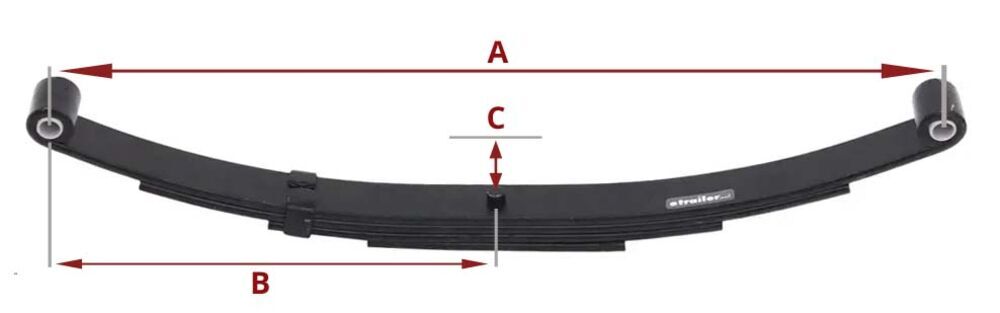

Leaf Springs

Cracked Broken Extremely rusty Overly worn and sagging You are upgrading the axle to a greater weight capacity

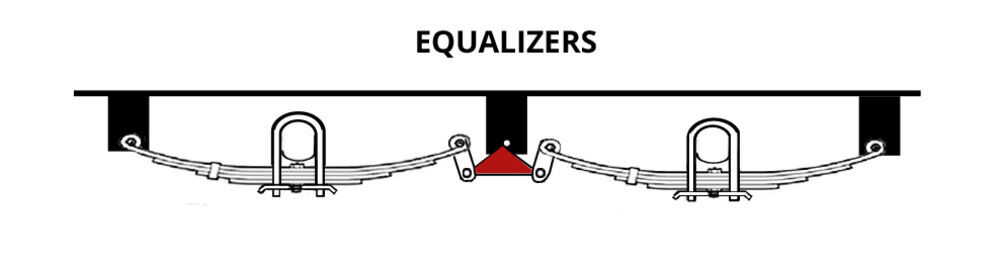

Equalizers

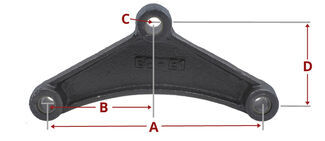

Flat (A): Generally used for horse trailers Tall (B): Designed to allow a trailer to ride low in RV applications Curved (C): Most common; found on utility trailers and car haulers Short curved (D): Typically used with short springs, on which front and rear hangers are close together

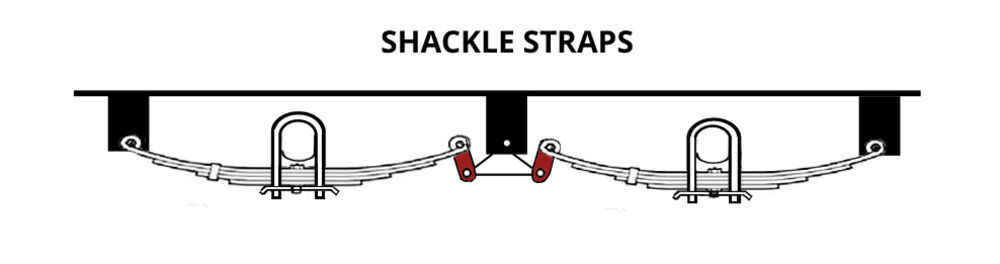

Shackle Straps

Severe rust Bolt hole openings become elongated or oval shaped Bolt and nut appear to be moving closer to edge of shackle

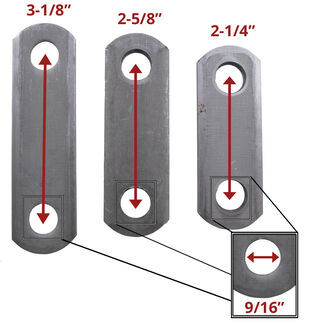

3-1/8" - Typically used on single-axle systems 2-5/8" - Most popular; typically used on dual-axle systems and all triple-axle systems 2-1/4" - Typically used in 1 dual-axle kit Bolt hole diameter (all) - 9/16"

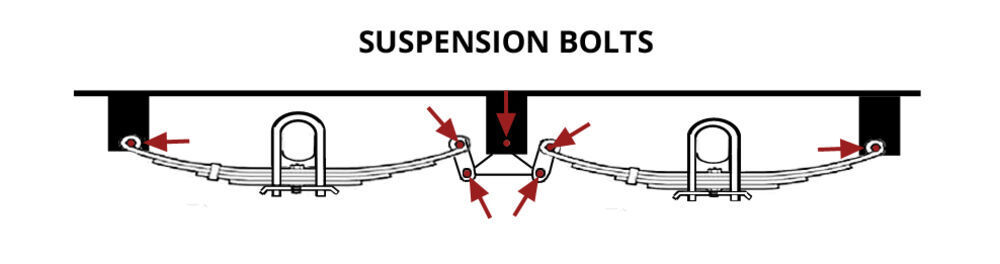

Suspension Bolts

Regular shackle bolts (A) - For use between springs/hangers and between slippers/hangers Wet shackle bolts (B) - Have zerk fittings that allow grease to be injected, which assists movement and halts corrosion. Can be used anywhere in system as long as bolt is appropriate size (eyes with bushing often do not need wet bolts) Equalizer bolts (C) - Suspend equalizers

Regular nut (D) - Standard nut; reusable Lock nut (E) - Has mismatched threads to ensure nut cannot twist off bolt; one-time use Castle nut (F) - Looks like castle wall; includes cotter pin, which threads through small hole at threaded end of bolt (ensures nut cannot come off bolt); most often used on equalizers of systems with high weight capacities

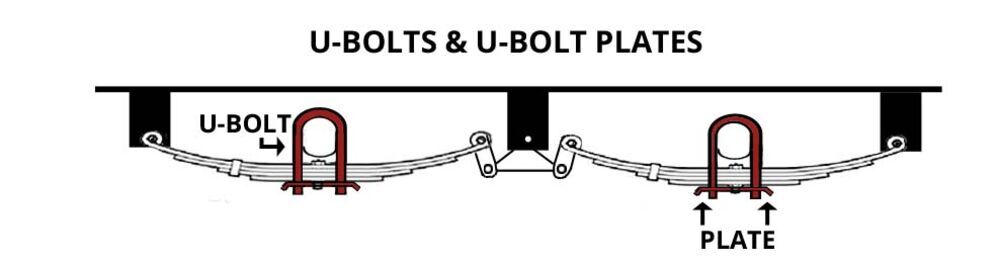

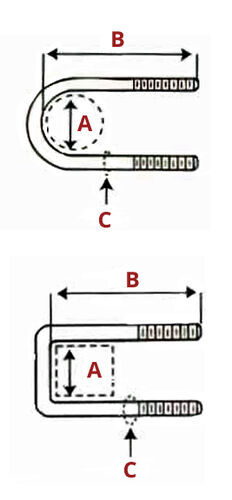

U-Bolts and U-Bolt Plates

Torque ratings: 1/2" bolts: 45 ft/lbs - 70 ft/lbs 9/16" bolts: 65 ft/lbs - 95 ft/lbs 5/8" bolts: 100 ft/lbs - 120 ft/lbs

Rusted Stretched Bent Show stress cracks or worn spots Show other significant signs of wear

1,000-lb - 2,000-lb Axles: 1-1/2" - 1-3/4" diameter 3,500-lb Axles: 2-3/8" diameter (can have a 3-1/2" diameter, but rarely) 6,000-lb - 7,200-lb Axles: 3" diameter 8,000-lb Axles: 3-1/2" diameter 9,000-lb Axles: 4" diameter 10,000+ lb axles: 5" diameter

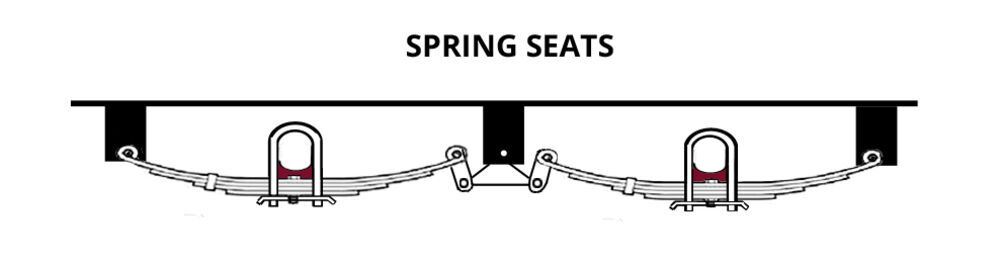

Spring Seats

Christopher

3/28/2023

I bought a used trailer that I need to replace the entire suspension system. Since the trailer rides quite low Im wondering about putting the axels on the bottom of the leaf springs instead of hanging them from on top, is this allowed?

Dustin G.

2/25/2023

I bought a used 18 ft trailer and the back leaf on the front of the left where the shackles connect to it was touching the frame … but only on the passenger side ???????. After ordering all new hardware .. it don’t touch no more but is real close to touching and I don’t have any weight on the trailer … and suggest??? Pics below !! Of before and after !!

Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"Very easy process, good prices and my products were shipped on time and were delivered on time. The instructional videos online helped make installation easy!"

Popular Vehicles

- Subaru Forester

- Ford F-350 Super Duty

- Ford F-250 Super Duty

- Chevrolet Silverado 1500

- Jeep Wrangler Unlimited

- Jeep Wrangler

- Ram 3500

- Toyota Highlander

- Ram 2500

- Chevrolet Silverado 2500

- Subaru Outback Wagon

- Chevrolet Silverado

- Dodge Ram Pickup

- GMC Sierra 2500

- Ram 1500

- Ford F-250 and F-350 Super Duty

- Jeep Grand Cherokee

- Toyota Tacoma

- GMC Sierra 3500

- Toyota Tundra

- Ford Escape

- More >>

Usman

4/11/2024

I bought a 25 ft double axle RV trailer. while turning a little road turn lot of tuk tuk noise from the wheels. what it could be ?